https://www.d-shannon-aviation.com/bonanza-exhaust.html#sigFreeIdf9e97749e8

INTRODUCING OUR NEW

HIGH PERFORMANCE EXHAUST!

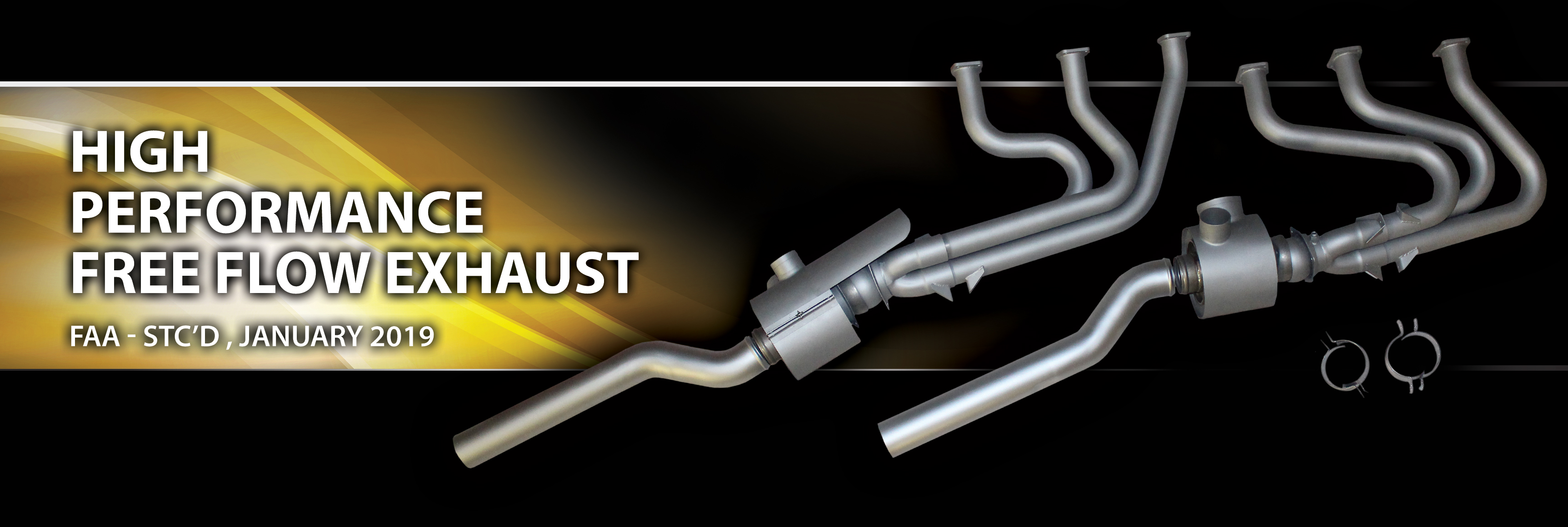

D’Shannon’s work to develop an exclusive high performance exhaust system (patent pending) has been underway for some time now. It is now available for the IO-550, IO-520, and the IO-470N on Bonanzas and Debonairs. The Baron G58, 58, E55, D55, and C55 will be available for delivery in January, 2019. It should be noted that the Beechcraft exhaust system for the IO-550 and IO-520 was originally designed for the IO-470 engine with 260hp. This is one of the main reasons the engines of today do not generate all of the horsepower they are capable of producing.

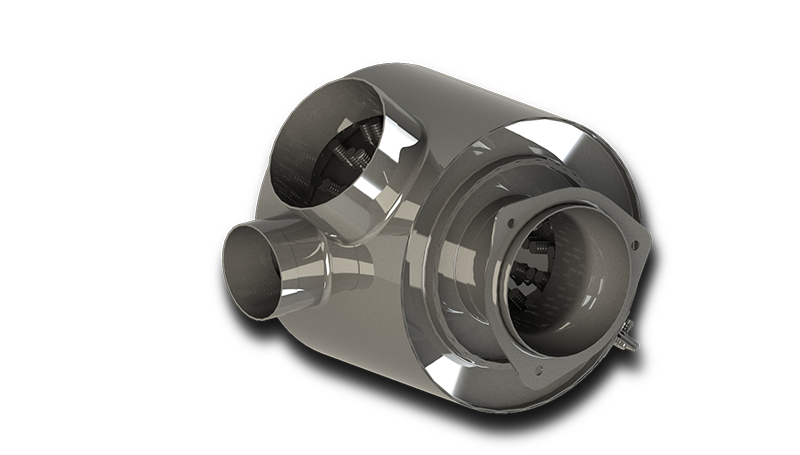

Using state of the art CNC equipment and proprietary tooling, along with the finest 321 Stainless Steel tubing, D’Shannon has developed a complete performance exhaust system for the Bonanza and Baron. We work with a premiere FAA approved exhaust manufacturer. The system has essentially no welding to distort the airflow, as well as exact uniform tubing lengths to provide balanced release of power per cylinder. Additionally, D’Shannon’s design includes dual heater muffs (heat exchangers) for substantial increase in cabin and defrost heater capacity. Finally, the complete exhaust system is ‘ceramic coated’ to protect and insure that the heat from the exhaust is forced out the exhaust system reducing the heat transfer into the engine compartment.

It should be noted that the exhaust system is critical to the performance of an aircraft engine. The narrow RPM range and the lack of space in the engine cowl make it a challenge to provide a system that will perform. For this reason and many others the approval has taken a protracted period of time. We were able to meet and exceed the high standards of Genesis Engines by D’Shannon and bring this system to owners of the IO-550, IO-520 and IO-470 engines.

Do the very best for your engine…

Install the High Performance Free Flow Exhaust by D’Shannon!

Patent pending for complete system

SYSTEM BENEFITS!

- The D’Shannon system takes full advantage of the available horsepower in the engine, allowing the engine to breathe more efficiently and relieve undue stress on the engine and internal parts.

- The primary reason for this is due to the thoughtful engineering and testing that went into the development of the system.

- Equal length primary header tubes and proprietary merge collectors.

- Smooth radius bends.

- Elimination of welding and weld points to allow more efficient evacuation flow of exhaust gases, yielding more horsepower.

- Largest diameter tubes feasible.

- Collectors and tailpipes designed to scavenge exhaust pressure.

- Material chosen for maximum durability and ease of installation.

- Exterior ceramic coating to protect engine and compartment from additional heat transfer, causing the heat to accelerate through the pipes.

- By providing dual heat collectors (one on each side of the engine) improved defrost and cabin heat is provided.

- This system has been well thought out by our certified Engineers and experienced technical staff. Their years in the racing industry and due diligence have yielded the highest quality exhaust system for the Beechcraft fleet in the marketplace today.

- Potential fuel savings, allowing same performance with lower consumption.

- Last but not least is the pride of ownership. Knowing you have the most efficient and durable ‘exhaust system’ in the market place today

https://www.d-shannon-aviation.com/bonanza-exhaust.html#sigFreeIdf9e97749e8

© 2024 D'Shannon Aviation || All Rights Reserved