Tip Tanks by D'Shannon

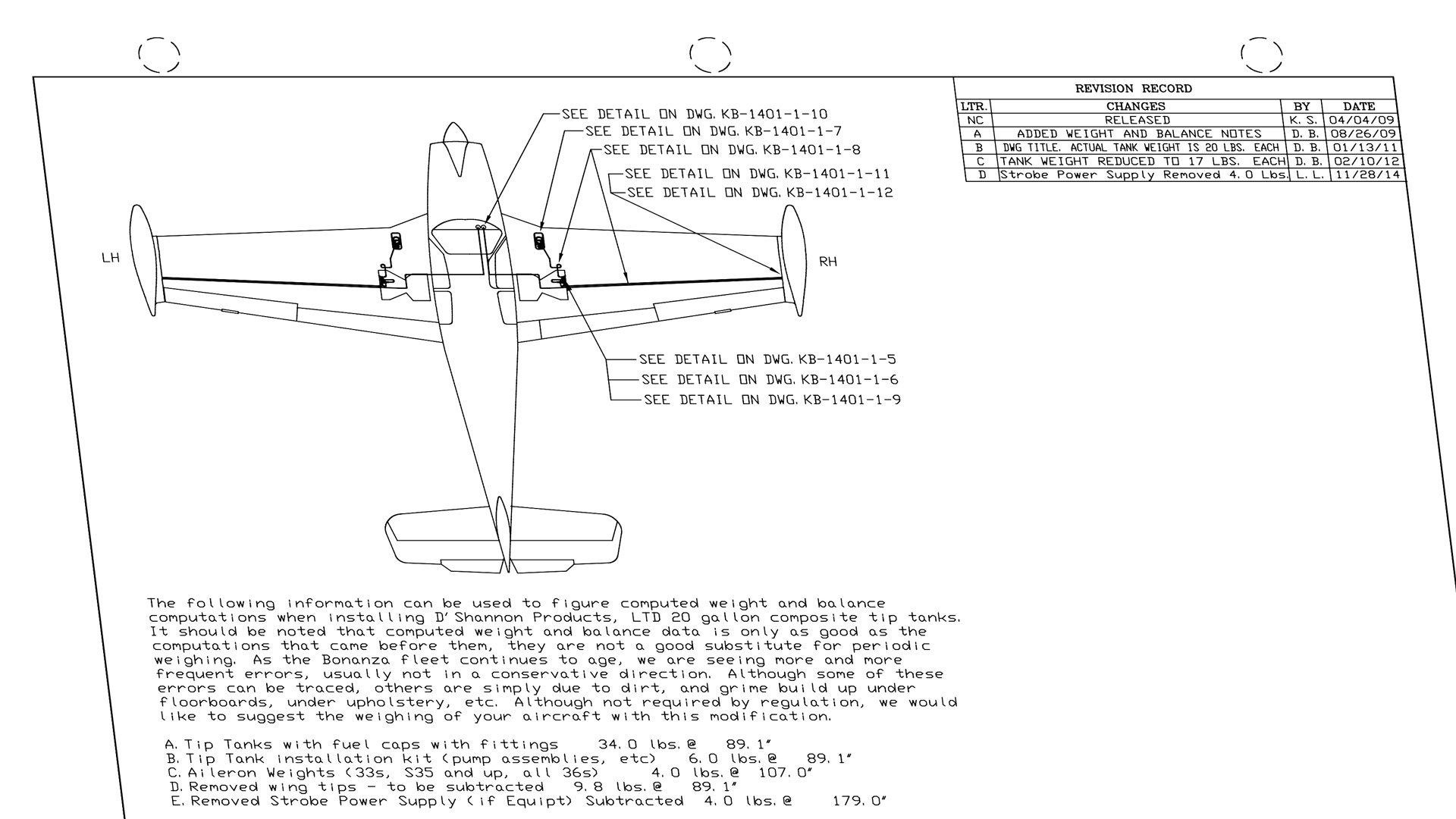

D'Shannon Aviation is synonymous with Beech Bonanza tip tanks for a reason: For over 50 years, D'Shannon has done tip tanks best. D'Shannon Aviation auxiliary tip tanks give you the added range and safety of 40 additional gallons of fuel for Bonanza or Debonair. The advantages of D'Shannon tip tanks include:- A Gross Weight Increase approved for all models.

- Extended range for fewer stops and quicker block-to-block trip times.

- Ability to "tanker" fuel to take advantage of low-cost fuel and bypass expensive fuel stops.

- Over two hours of additional fuel for IFR flexibility and reserves.

D'Shannon's Tip Tank Advantage

| Features | Benefits |

|---|---|

| 1. Modern Canted Aerodynamic Design | Increased lift |

| 2. Made from the latest in Composite Technology | |

| 3. Newly improved Tip Tank Visual Sight Gauge | |

| 4. Light Emitting Diode (LED) Navigation, and Position lighting with LED Strobes all three locations | |

| 5.Pocket for left wing Magnetometer engineered into tank with volume compensation | |

| 6. Exclusive Genesis Conversion for models 36, A36, A36TC and G36 includes a complete D'Shannon Baffle Kit and Gap Seal Kit | |

| 7. Hawker Beechcraft Approved for post delivery on G36. We work with the very best! | |

Tip Tank FAQs

Out of 40 Gallons total, 40 Gallons are useable.

Both the Pulsar NS and the Suntail are rated for 50,000 hours by AeroLEDs.

40-50 Hours, If you have strobes an extra 5-10 hours will be required to remove the strobe power supply, however if your plane doesn't currently have strobes an extra 10-15 hours will be required to run the new wiring.

Yes, We use AeroLED's Pulsar NS for nav & strobe and AeroLED's Suntail for the tail, Alternatively you may choose to have Whelen's Orion 650 Series installed for the nav & strobe and Whelen's Orion 500 for the tail

Yes, we hold the supplemental type certificates "STC" along with a FAA parts manufacturing approval(PMA).

Yes, you can give us a call toll free at (800) 291-7616, or Here

It will cause the wing span to increase by about 3 inches per side.

The tip tanks weigh 34 pounds for the set.

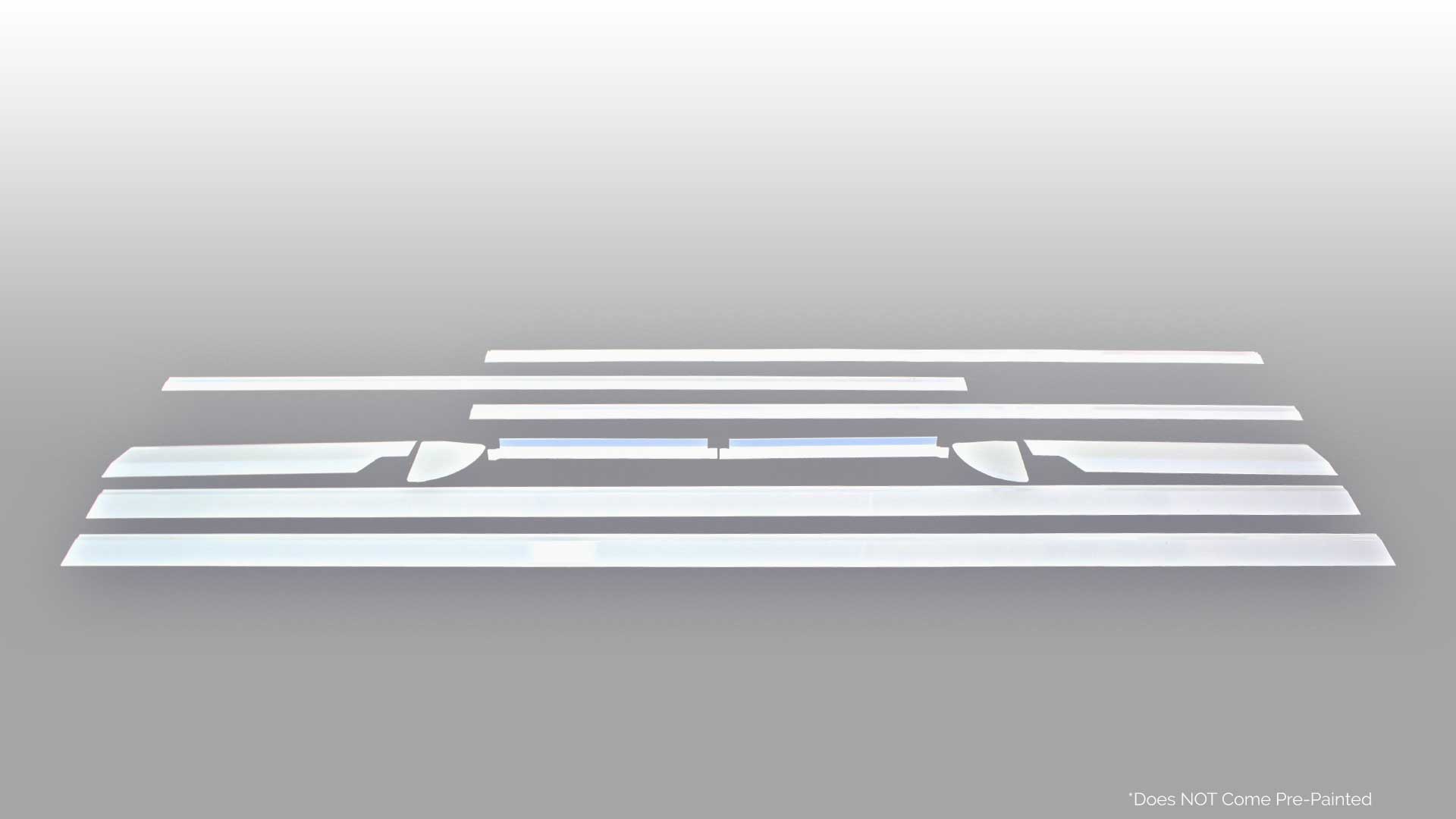

No, but our tanks are sent out fully primed and ready to paint.

Anyone can install the tip tanks, but an IA(Inspection Authorization) rating is required following the approval of a tip tank installation inspection

Simply install the tip tanks, you are then able to take advantage of the GWI associated with the STC.

The gross weight increase varies from model to model and can be obtained Here.

Even at Max Gross Weight fuel is not required.

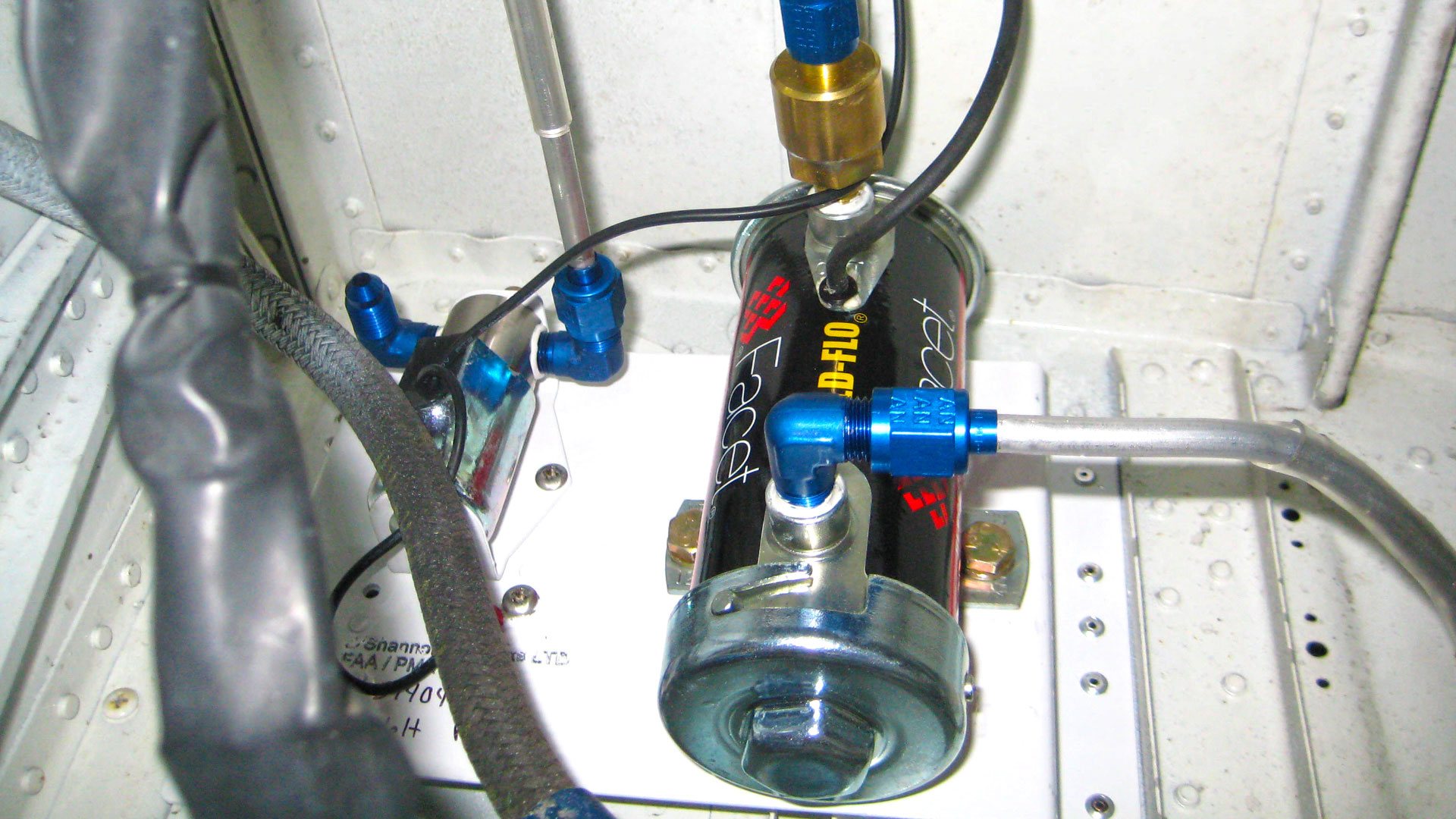

The fuel in the Tip Tanks is pumped into the Main Tanks. A switch is installed in the instrument panel to enable the transfer pumps. Insure you burn sufficient fuel from the Main tanks prior to activating the transfer pump. If the Main tank is pumped past full, excess fuel will be vented overboard.

Yes we do. There are three approaches you can take depending on the severity of the degradation of the sight strips. The degradation occurs due to the natural UV exposure of the resin to the sun’s rays. On the rest of your tip tank, the paint protects the resin from the sun’s UV rays, but the sight strips are left clear to provide visibility of the fuel level. If the degradation becomes severe enough, some of the glass fibers may start to show at the surface of the resin in the sight strip area.

First, for minor degradation where the sight strip is cloudy, but there is no exposure of the underlying fibers through the resin, we carry a product called Armor-Dillo TS-1 that works well. Armor-Dillo TS-1 is silicone free, paint shop friendly, and will restore the original gloss and visibility of the sight strip. One application should last 3-6 months with no greasy or slippery residue. Apply TS-1 the sight strip area and wipe off excess with a wet towel. Do not allow TS-1 to dry on painted surfaces, remove immediately with damp cloth if contact occurs. TS-1 packaging includes the following cautions:

CAUTION: Flammable!

Do not use around open flame! Possibility of spontaneous combustion exists with this product. Do not re-use container for future use. Disposal: Rinse rags with water and lay flat until dry. Us in well ventilates area. For external use only. First aid: Eyes: Immediately flush eyes with water for 15 minutes. If irritation persists, seek medical attention. If swallowed: Call the poison control center, hospital, emergency room or physician immediately for instructions. Skin irritation: Wear rubber gloves and protective clothing while handing TS-1. Wash hands with soap and water after use.

Second, for more severe degradation where the glass fibers are showing through the resin, we recommend reapplying a quality resin to the exterior of the sight strip to seal the glass fibers and to make the sight strip clear again. Mask off the surrounding paint area and sand the affected area with 180 grit sand paper. Use a quality marine grade resin that has a medium thickness such as Evercoat Premium Marine Resin that will not sag off the vertical sight strip. Mix the catalyst and resin according to the manufacturer’s instructions. Improper mixing may result in a repair that does not completely dry hard (remains sticky) or one that does not flow out properly. Apply in a thin, uniform layer until all the fibers are covered. Reapply if needed after roughing the surface again with the 180 grit sand paper. This repair will give several years of useful service as marine grade resins have some UV protection built in.

Third, for a longer service life, after finishing the strip with the quality marine grade resin, or if fiber glass strands are not emerging from the surface of the sight strip, clear the surface of the sight strip with a quality automotive clear coat. The clear coat will protect the surface from the UV rays as well as smoothing the surface to make the sight strip translucent. Be sure to follow the manufacturer’s recommendations for the clear coat, including any surface preparation (clean, wax and silicon free, and roughened with the proper grit paper) and mixing instructions for the two part catalyzed system you are using.

You may be wondering why D’Shannon doesn’t prepare the sight strip with clear coat in the first place. Our tip tanks are delivered primed and ready for the surface finish of your choice. Masking off the sight strip to preserve its use is a good practice when applying the paint finish to the tanks. In many cases the paint applied is single-stage with no clear coat applied. When you have your tanks painted, ask the finisher to apply a clear finish to the sight strip area to provide additional UV protection, even if the rest of the tank is finished with a single stage product.

Tip Tanks Manuals

Features of D'Shannon Tip Tanks Include:

- Three separate filters in the system as fuel passes from the tip tanks to the main tanks.

- Flip-style fuel caps (the same as on main tanks) and quick drains are flush-mounted for improved aerodynamics and appearance and double o-ringed for a positive seal.

- No internal rubber bladders, as found in the main fuel cells. These tanks can also be left empty without any adverse effect.

- Our tip tanks are a direct replacement for the original wing tips so no modification of the wing is required.

Get More Info

The Tanks

include LED navigation lights and are pre-wired for strobes (available separately). We also offer an all LED nav and strobe package with AeroLED lights(Suntail and Pulsar NS). Check out this article. Also look for more information on the AeroLED lights in the tip tank document section. Fuel quantity may be monitored by your choice of panel-mounted gauges and/or clear sight strips located on the tanks.Get More Info

Fuel is Transferred

from the tip tanks to each respective main tank by fuel pumps mounted in the wheel wells. These fuel pumps are controlled by panel-mounted toggle switches. D'Shannon Aviation pumps have been in use for over 30 years and have proven to be very durable. In fact, D’Shannon fuel pumps do not require complicated auto shut-off devices because the pumps can run "dry"indefinitely with no damage.Get More Info

D'Shannon Tip Tanks

are constructed of high impact, fuel resistant Fiberglass®. D’Shannon Aviation uses the same quality Fiberglass® materials found in military applications such as radomes and missiles. Our signature 20-gallon tip tanks have less drag than our previous 15-gallon models due to an improved slenderness ratio, even though the 20-gallon tanks have a greater frontal area. The new canted cuff was developed to maximize the endplate effect of the tip tank, which increases the aerodynamic efficiency of the wing. This upgrade also eliminates the need to relocate the magnetometer in the left wing. Only the D’Shannon Aviation tip tank includes an aileron re-balance kit to provide the maximum of safety in high altitude, full power, high speed flight. Revised aileron balance specifications eliminate the vibration often experienced in tip tank-equipped Bonanzas by dampening the torsion frequencies in the wing through the ailerons. This protects you from possible control reversal or control damage.Get More Info

© 2026 D'Shannon Aviation || All Rights Reserved